PVD Hard Coating

PVD hard coating is one of the best methods for optimising the hardness to residual compressive stress ratio. It uses a similar vacuum deposition coating method as the standard PVD coating that coats the product with a film of hard refractory material 2-7 microns thick. The differences between PVD hard coating and the standard PVD coating are:

- The materials enclosed in the vacuum chamber are heated to a maximum temperature of 500 celcius

- The duration of the coating time is longer

- 10x hardness

- Titanium Nitride(TiN)

- Titanium Carbo-Nitride(TiCN)

- Chromium Carbide(CrC)

- Aluminium Titanium Nitride(AlTiN/TiAlN)

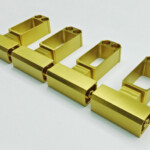

Titanium Nitride (TiN)

Types of Coating : Titanium Nitride (TiN)Hardness (HV) : 2000 - 2750

Thickness (µm) : 2 - 5

Colour : Gold

Coating Temperature (°C) : ~350

Titanium Carbo-Nitride (TiCN)

Types of Coating : Titanium Carbo-Nitride (TiCN)Hardness (HV) : 3000 - 3500

Thickness (µm) : 2 - 5

Colour : Greyish-Black

Coating Temperature (°C) : ~500

Chromium Carbide (CrC)

Types of Coating : Chromium Carbide (CrC)Hardness (HV) : 3000 - 3500

Thickness (µm) : 1 - 3

Colour : Dark Grey - Black

Coating Temperature (°C) : ~350

Aluminium Titanium Nitride (AlTiN) / Titanium Aluminium Nitride (TiAlN)

Types of Coating : Aluminium Titanium Nitride (AlTiN) or Titanium Aluminium Nitride (TiAlN)Hardness (HV) : 2900 - 3300

Thickness (µm) : 1.8 - 3.5

Colour : Dark Grey - Black

Coating Temperature (°C) : ~400 - 425